Pipe support insulation

Traditionally, pipe insulation boards have been supported by simple wooden blocks or dowels at the hanging location. However, the changing environment, the increasing environmental concerns, especially with regard to mold and mildew, coupled with the increasing focus on sustainable construction, have led engineers to re-evaluate their support systems for optimum performance. Furthermore, modern regulations often require colder piping systems for chilled water and other cold water pipes, which require a wider range of pipe insulation support options than currently available from manufacturers. This change in regulations has led to a re-evaluation of the methods and materials traditionally used to support pipe insulation. As a result, the industry is facing a trend towards more innovative, environmentally friendly, and versatile solutions that can effectively meet these new challenges while maintaining the integrity and performance of the piping system for a variety of applications.

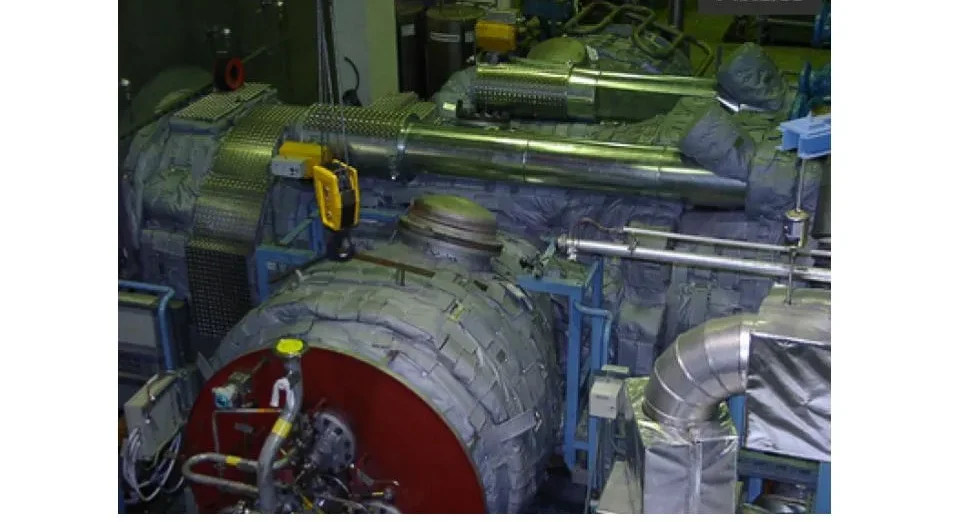

Hot insulation for machines

High-temperature surfaces on engines and exhaust pipes pose significant risks to both equipment and personnel. These high temperatures can severely damage nearby components such as control switches, wiring and motors. They also pose serious safety hazards to operators who may inadvertently come into contact with these hot surfaces during handling or maintenance.

To address these challenges, an effective and cost-effective solution is to use fiberglass cloth in combination with high-temperature insulating materials such as mineral wool or ceramic wool. This combination provides excellent thermal protection while remaining relatively affordable.