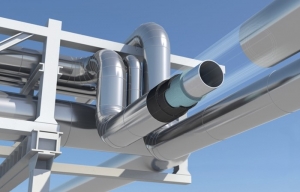

Cryogenic insulation

Risk of the insulation system for a very low line like the LNG, is the corrosion under insulation. This kind of pipeline failure cost the operator not only the insulation cost, but the operating loss is the worse that the LNG business can not tolerate. Moreover, the time of the installation this kind of insulation is longer, therefore the labor cost is higher.

Our Expertise

ASA provides a multilayer elastomeric system to replace the conventional rigid foam on this low process pipe work. This kind of foam combine in a single material the key performance qualities that are traditionally only achieved through the labor-intensive combinations of several other materials (e.g. rigid foams combined with vapor retarders and contraction joints). They combine low thermal conductivity, in a light-weight (low density) foam that remains flexible at low temperatures. This flexibility provides a system that inherently absorbs vibrations and iimpact, to provide a robust and low-maintenance solutions to the insulation of cryogenic pipelines, vessels and equipment.